Click on each question below to jump to the

corresponding answer about our aftermarket airplane

spoilers. If you have you have further

questions you would like to have answered, please see

our contact page or call

us at 253-851-1769.

What is the Purpose of

the Spoiler on an Airplane?

Why Aircraft Spoilers?

Why PowerPac Spoilers?

How Do PowerPac Aircraft Spoilers Work?

Have the PowerPac Spoilers been Thoroughly Tested?

Are the Spoilers made from Quality Components?

Remember:

- With PowerPac Spoilers you command descent rates up to

3.5 times faster!

- Avoid engine shock cooling and maintain cabin

pressure.

- Plus you can deploy and retract PowerPac Spoilers in

Icing Conditions.

- When it’s time to come down you’ll be very glad you

have PowerPac Spoilers.

The spoiler on an airplane allows the pilot to set a

desired descent rate at any altitude without having to

change the power setting, thereby eliminating any chance

of engine damage caused by shock cooling the engine.

Deploying the airplane spoiler in level flight reduces

excessive airspeed without making any major power

change. The spoiler aids the pilot in getting down

fast and safely in extreme turbulence and icing

conditions.

• The addition of aftermarket spoilers to your

aircraft provides an additional

dimension of control that will transform the

manageability of your airplane's descent

characteristics.

• Rapid descents may be made without having to reduce

power, thereby maintaining engine temperatures at a

comfortable level, and eliminating the risk of engine

"shock cooling."

• Maintain normal cruise/descent speeds until much

closer to the airport without worrying about how you'll

slow to gear extension speed.

• Deploying Spoilers instead of reducing power and/or

lowering the landing gear will safely accomplish rapid

reduction in airspeed.

• Descend rapidly through icing conditions without risk

of accumulating additional ice on extended landing gear

surfaces.

• Reap the benefits of high altitude flight longer. Take

advantage of tailwinds and smooth air until you are much

closer to your destination before beginning your

descent.

• Comply with ATC descent clearances or speed reduction

requests with confidence. Eliminate the need for such

awkward procedures as extending the landing gear … then

having to retract it once the request has been met.

«BACK TO

FAQs

• Thoroughly tested and operational in icing conditions.

This is especially beneficial when a descent is required

through cloud layers in which significant ice

accumulation has been reported. In many situations, the

use of Spoilers will minimize the time spent in actual

icing conditions.

• PowerPac Spoilers are true Spoilers. When deployed

they function to reduce lift rather than merely increase

drag. Lift induced loads carried by the wings are

actually reduced during Spoiler deployment.

Consequently, many pilots find it beneficial to use

PowerPac Spoilers to slow the airplane when sudden

unexpected turbulence is encountered.

• Hydraulic operation practically eliminates the chance

of asymmetric deployment.

• Fail-safe design. Loss of electrical power for any

reason causes the Spoilers to retract.

• No operating restrictions. Spoilers may be deployed in

any configuration and at speeds up to Vne.

• High quality precision machined components. PowerPac

Spoiler actuators and hydraulic pump parts are

manufactured by computer programmed milling machines

from solid aluminum billet alloy stock and hardened

steel.

• The PowerPac Spoiler system takes up no room in any

passenger or baggage areas (in most types, call for

details).

«BACK TO

FAQs

How Do PowerPac Aircraft Spoilers

Work.

PowerPac Spoilers “Jet Type” design is similar to those

used on commercial jet airliners. The system consists of

single flat plates, one on top of each wing that lies

flat when not in use. When deployed, they extend upward

into the slipstream at a 60-degree angle, thereby

"spoiling" a portion of the lift being generated by the

wing, while at the same time creating drag.

The operating system is hydraulic. All kits (except for

the Aerostar) employ an electric-hydraulic pump or

PowerPac to supply hydraulic pressure. The Aerostar

design consists of a manifold that directs hydraulic

pressure from the airplane system to the two wing

actuators.

In the unlikely event of a leak, the drop in pressure

affects deployment of each spoiler equally, eliminating

for all practical purposes, the chances of asymmetrical

deployment. In addition, if a leak occurs in the Spoiler

circuit of the Aerostar, an automatic timer signals a

solenoid valve to close, isolating the Spoiler hydraulic

circuit from the airplane's system.

Spoilers are deployed when the pilot pushes a "one-touch

button" on the instrument panel. This applies power to

the hydraulic pump or, on the Aerostar opens a valve on

the manifold. In either case hydraulic pressure is

applied to each Spoiler wing actuator.

When the Spoilers are fully deployed, i.e. 60 degrees up

position, limit switches on each actuator close,

shutting off hydraulic pressure, turning on an

annunciator light in front of the pilot for each

Spoiler, and applying power to a second hydraulic

solenoid (fail-safe) valve. This valve traps hydraulic

pressure in the Spoiler circuit lines keeping the

Spoilers deployed until there is an interruption of

electrical power.

If the pilot pushes the button a second time, or if

power is removed from the fail-safe solenoid valve for

any other reason, (such as an aircraft electrical system

failure) the valve opens allowing hydraulic fluid to

flow back into the reservoir. Aerodynamic pressure on

the Spoiler panels, in addition to return springs,

insures immediate retraction of the Spoilers as the

hydraulic pressure dissipates.

«BACK TO

FAQs

PowerPac Spoilers Have

Been Thoroughly Tested.

Initial flight-testing of a variety of Spoiler plate

sizes in various locations on the wings is performed

before a design configuration is finalized. Target

performance for the Spoilers is an increase in descent

rate of between 50 and 100 percent of what it would be

without them. Additional goals include minimizing

"spoiler rumble" and pitch change during deployment.

Elaborate stall testing is undertaken with all possible

combinations of gear position, flap position and CG

range included. The purpose is to see that there is no

diminution of control affectivity, no adverse change in

stall characteristics and no substantial increase in

stall speeds when the Spoilers are deployed.

Asymmetric deployment testing is performed to insure the

airplane remains fully controllable in the highly

unlikely event that one Spoiler fails to retract (or to

deploy). Test flights are made with only one Spoiler

deployed that includes high-speed dives, stalls,

landings and go-arounds. Even in the worst-case

situation (high-speed), less than 10 lbs of force on the

yoke is required to maintain wings level.

High-speed test flights are made with Spoilers deployed

at speeds up to Vd (design maximum dive speed). This

speed is redline plus 10% and is allowable only for test

purposes on an airplane specially licensed by the FAA in

the experimental category. These flights are made to

insure, among other things, that no unusual

controllability problems or vibrations occur at higher

indicated airspeeds.

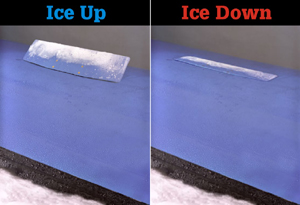

FAA requirements to test for successful operation

in icing weather were very difficult to accomplish.

Repeated test flights in icing conditions failed to

produce any accumulation anywhere close to the Spoilers.

Consequently it was necessary to create an artificial

ice accumulation on and around the Spoiler plates. With

the Spoilers in the retracted position, wing and Spoiler

surfaces were reduced to subzero temperatures, then

subjected to a continuous spray of water until the area

was coated approximately 1/2" thick with ice. When

commanded to deploy, the system had more than adequate

power to break the ice and reach its normal 60-degree

position. A similar test with Spoilers deployed during

ice accretion demonstrated that when retraction is

called for, the panels will return to within 1/4" to

1/2" of flush. This position is well below the airflow

boundary layer and creates no significant affect on

lift/drag. FAA requirements to test for successful operation

in icing weather were very difficult to accomplish.

Repeated test flights in icing conditions failed to

produce any accumulation anywhere close to the Spoilers.

Consequently it was necessary to create an artificial

ice accumulation on and around the Spoiler plates. With

the Spoilers in the retracted position, wing and Spoiler

surfaces were reduced to subzero temperatures, then

subjected to a continuous spray of water until the area

was coated approximately 1/2" thick with ice. When

commanded to deploy, the system had more than adequate

power to break the ice and reach its normal 60-degree

position. A similar test with Spoilers deployed during

ice accretion demonstrated that when retraction is

called for, the panels will return to within 1/4" to

1/2" of flush. This position is well below the airflow

boundary layer and creates no significant affect on

lift/drag.

All major system components are bench tested before

shipping. Hydraulic Spoiler actuators are installed in

test jigs that simulate a 300 knot indicated airspeed

for one hour. Every PowerPac hydraulic pump is similarly

subjected to loads in excess of what it will encounter

in normal operations. These tests are designed to show

up leaks or other malfunctions.

«BACK TO

FAQs

|